The Boeing 757 is a twin-engine, narrow-body aircraft that has long been favored by airlines for its versatility and efficiency. Understanding the price and operating costs associated with the Boeing 757 is crucial for airlines, operators, and aviation enthusiasts alike. In this comprehensive article, we will delve into various aspects, including the purchase price, operating expenses, maintenance costs, and factors influencing these costs.

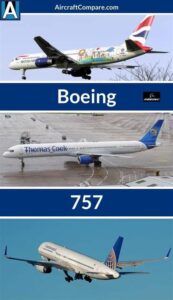

1. Overview of the Boeing 757

Before discussing the financial aspects, it’s essential to understand what makes the Boeing 757 a unique aircraft. Introduced in the early 1980s, the 757 was designed to fill the gap between smaller regional jets and larger wide-body aircraft. With a seating capacity ranging from 200 to 280 passengers, depending on the configuration, the 757 is ideal for medium to long-haul flights. Its range of approximately 3,915 nautical miles (7,250 km) allows airlines to operate routes that would be unfeasible for smaller aircraft.

2. Purchase Price of the Boeing 757

The purchase price of a Boeing 757 can vary significantly based on several factors, including age, model variant, and condition. As of recent estimates, the price for a new Boeing 757 can range from $100 million to $120 million. However, since the production of the 757 ceased in 2004, most transactions involve used aircraft.

2.1 Used Boeing 757 Prices

The secondary market for the Boeing 757 has seen prices fluctuate based on demand and supply dynamics. Typically, used Boeing 757s can be found for prices between $15 million and $50 million. Factors affecting these prices include:

-

Aircraft Age: Older models tend to be less expensive but may require more maintenance.

-

Flight Hours: Aircraft with lower flight hours generally command higher prices due to perceived reliability.

-

Modification and Upgrades: Aircraft with modern avionics or cabin upgrades can fetch higher prices.

3. Operating Costs of the Boeing 757

Operating costs are a critical consideration for airlines when determining the viability of any aircraft. The Boeing 757 has relatively low operating costs compared to other aircraft in its category, making it an attractive option for many airlines.

3.1 Direct Operating Costs (DOC)

Direct operating costs encompass all costs directly associated with the operation of the aircraft, excluding capital costs. For the Boeing 757, direct operating costs typically average around $5,000 to $7,000 per hour. Key components of these costs include:

-

Fuel Costs: Fuel consumption is one of the most significant operating expenses. The Boeing 757 burns approximately 5,000 to 6,000 pounds of fuel per hour, translating to roughly $1,500 to $2,000 in fuel costs, depending on current fuel prices.

-

Crew Salaries: The cost of crew salaries varies based on the airline’s pay structure and regulatory requirements. Typically, a two-pilot crew can cost around $800 to $1,200 per flight hour.

-

Maintenance Costs: Regular maintenance is crucial for safety and compliance. Maintenance costs can average around $1,000 to $1,500 per hour of operation.

3.2 Indirect Operating Costs

In addition to direct operating costs, airlines must also consider indirect operating costs, which include:

-

Landing Fees: These fees vary by airport but can range from $1,000 to $5,000 per landing, depending on the airport’s size and traffic.

-

Navigation Fees: Charges for air navigation services can add another $500 to $1,000 per flight.

-

Insurance Costs: Insurance premiums can range from $10,000 to $20,000 annually, depending on the airline’s operational history and risk assessment.

4. Maintenance Costs of the Boeing 757

Maintenance is a significant part of the total cost of ownership for the Boeing 757. Regular maintenance ensures safety and operational efficiency. The maintenance costs can be categorized into:

4.1 Routine Maintenance

Routine maintenance includes scheduled checks and inspections, which can cost between $250,000 and $500,000 annually. This encompasses:

-

A Checks: These are minor checks conducted every 400 to 600 flight hours.

-

B Checks: Performed every 6 to 8 months, these checks are slightly more extensive.

-

C Checks: Comprehensive checks conducted every 20 to 24 months, costing around $1 million each time.

4.2 Unscheduled Maintenance

Unscheduled maintenance refers to repairs needed due to unexpected issues. Costs can vary widely based on the nature of the problem, but airlines should budget for unexpected repairs as they can reach hundreds of thousands of dollars for major issues.

5. Factors Influencing Operating Costs

Several factors can influence the operating costs of the Boeing 757, including:

5.1 Fuel Prices

Fuel prices are volatile and can significantly impact operating costs. A rise in fuel prices directly increases the overall cost of operation, emphasizing the importance of fuel-efficient operations.

5.2 Flight Routes

The efficiency of flight routes affects operational costs. Shorter flights may lead to higher costs per mile due to takeoff and landing cycles, whereas longer flights can distribute costs more efficiently over greater distances.

5.3 Regulatory Compliance

Compliance with aviation regulations can also add to operating costs. Changes in regulations may necessitate modifications to the aircraft or additional training for crew members, leading to increased expenses.

5.4 Market Demand

The demand for air travel can affect pricing strategies, influencing how airlines manage their operating costs. Higher demand may lead to increased ticket prices, allowing airlines to offset higher operating costs.

6. Conclusion

In summary, the Boeing 757 remains a valuable asset for many airlines worldwide due to its efficiency and versatility. While the initial purchase price can range significantly, the overall operating costs are comparatively manageable, making it an attractive choice for operators. Airlines must carefully assess both direct and indirect costs, along with maintenance considerations, to ensure profitability and sustainability in their operations. Understanding these financial dynamics is crucial for making informed decisions in the aviation industry.